Checking Out the most recent Technological Technologies in Import Engines and How They Improve Driving Experience

In the world of automotive engineering, the landscape of import engines is undergoing a profound change driven by sophisticated technological developments. From the development of turbocharged engines to the assimilation of crossbreed technology, the most up to date improvements are changing the driving experience in ways previously inconceivable. As import makers press the borders of efficiency and performance via enhanced fuel injection systems and sophisticated engine management services, the concern occurs: How do these advancements truly influence the method we interact with our vehicles on the road?

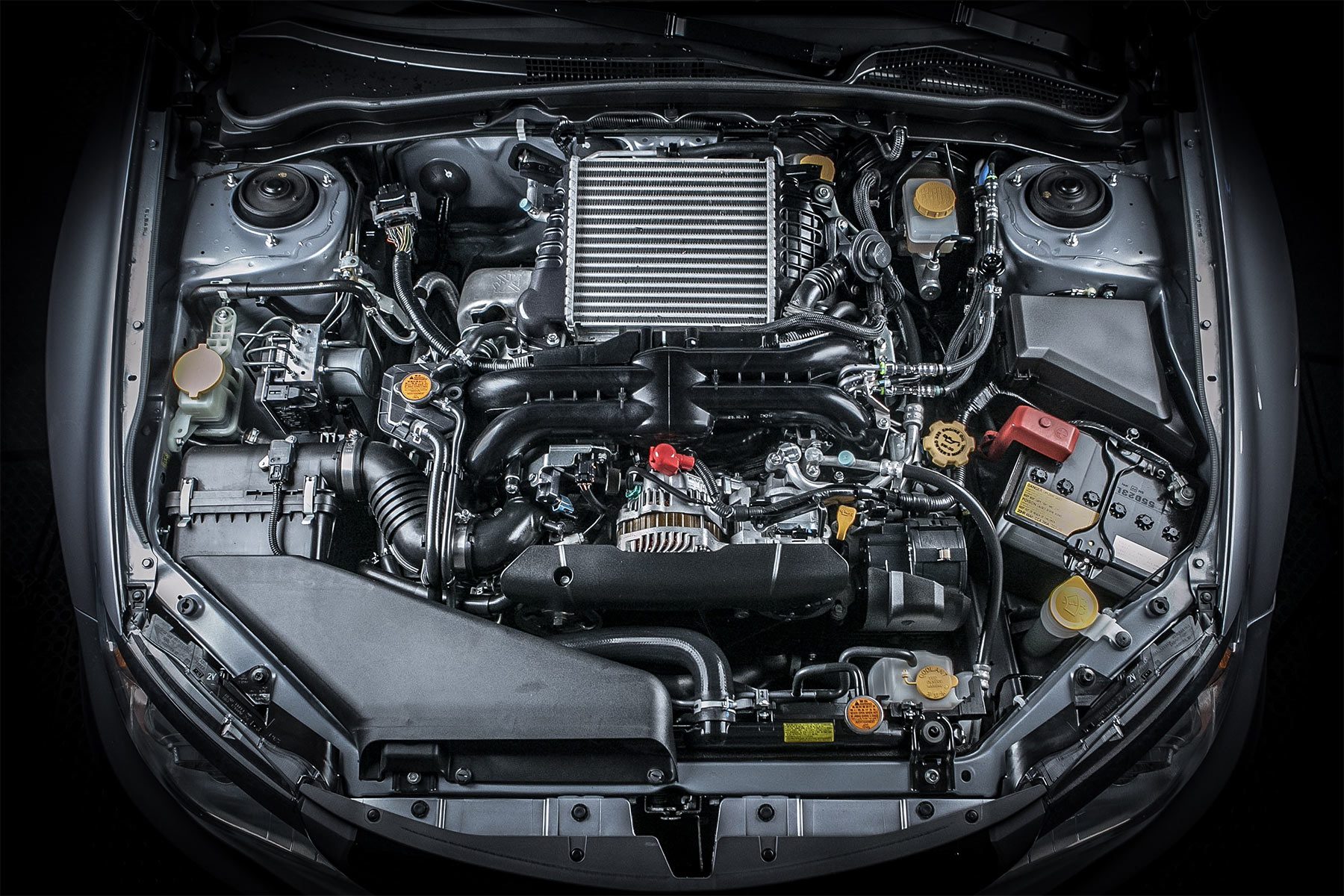

Evolution of Turbocharged Engines

In the automobile market, the development of turbocharged engines has actually dramatically changed the landscape of efficiency and performance. Turbocharging, as soon as primarily seen in high-performance sports vehicles, has now become a mainstream innovation embraced by a large range of automobiles, from small hatchbacks to deluxe sedans. The basic principle behind a turbocharged engine is basic yet efficient - forcibly even more air right into the combustion chamber, it enables more fuel to be burned, resulting in raised power result.

Among the vital advantages of turbocharged engines is their ability to supply more power from smaller sized, more fuel-efficient engines. This scaling down pattern has actually caused a reduction in emissions without endangering efficiency, making turbocharging an appealing choice for automakers making every effort to fulfill strict environmental regulations. Turbocharged engines use enhanced torque at reduced RPMs, supplying chauffeurs with an extra responsive and dynamic driving experience.

As modern technology continues to advance, we can anticipate further technologies in turbocharging, causing even higher levels of efficiency and efficiency in the auto market.

Innovations in Fuel Shot Solutions

Modern fuel injection systems have progressed to supply gas more effectively and exactly right into the engine cyndrical tubes, improving overall engine performance and fuel effectiveness. One of the crucial technologies in fuel injection systems is the shift from conventional port fuel injection (PFI) to more sophisticated straight gas shot (DFI) modern technology.

In addition, the integration of digital control units (ECUs) and sensors in gas injection systems has permitted real-time adjustments to sustain shipment based on various variables such as engine tons, temperature, and driving problems. This degree of precision makes certain ideal fuel-air mix proportions, maximizing engine performance while lessening fuel intake and discharges. Furthermore, developments in fuel injector design, products, and spray patterns have actually added to cleaner combustion and smoother engine operation. To conclude, the continual technologies in gas injection systems play an essential role in boosting driving experience by giving enhanced performance, fuel economic situation, and ecological friendliness.

Integration of Crossbreed Technology

The advancement of fuel injection systems towards greater effectiveness and performance has actually set the phase for the smooth combination of crossbreed innovation right into contemporary engines. Crossbreed innovation combines making use of traditional inner combustion engines with electrical propulsion systems, offering enhanced gas effectiveness and lowered emissions. By incorporating electric motors and batteries into the powertrain, crossbreed engines can supplement the internal combustion engine throughout acceleration or low-speed driving, consequently boosting dig this overall efficiency.

Improved Engine Administration Solution

What are the essential improvements in engine monitoring systems that are enhancing the performance and effectiveness of contemporary engines? Engine administration systems have actually undertaken substantial advancements to optimize engine performance and effectiveness.

Additionally, contemporary engine administration systems use innovative formulas and fabricated knowledge to assess the information accumulated by sensing units and make vibrant changes to variables such as ignition timing, gas shot, and my website turbocharger increase pressure. This level of precision and adaptability cause improved engine responsiveness, increased power result, and reduced gas intake.

Furthermore, engine administration systems now feature advanced diagnostic capacities that can find and address problems such as misfires, sensor malfunctions, and gas system irregularities in real-time, thereby boosting total engine dependability and durability. These innovations in engine monitoring systems play an important function in enhancing the driving experience by supplying optimal performance, gas efficiency, and dependability.

Effect of Lightweight Materials

Integrating light-weight materials in engine manufacturing has actually changed the vehicle industry's strategy to improving fuel performance and performance. Using products such as carbon titanium, fiber, and light weight aluminum has actually substantially decreased the total weight of engines, resulting in improved power-to-weight proportions and increased gas economy. These light-weight materials use a higher strength-to-weight proportion compared to standard products like steel, enabling better toughness without compromising efficiency.

Among the key advantages of using light-weight products in engine building is the decrease of inertia, causing quicker engine feedback times and boosted total lorry dexterity. In addition, the lighter weight adds to decrease energy usage, making lorries more ecologically pleasant by reducing discharges.

In addition, the implementation of lightweight products in engine parts such as pistons, connecting rods, and crankshafts has enabled designers to press the limits of performance without sacrificing dependability (import engines). This development has led the way for much more powerful and reliable engines that deliver a premium driving experience while satisfying strict exhausts requirements

Conclusion

To conclude, the most recent technical developments in import engines have dramatically improved the driving experience. From the evolution of turbocharged engines to improvements in gas shot systems, combination of hybrid innovation, improved engine administration systems, and the use of lightweight materials, these developments have collectively improved efficiency, gas performance, and general driving characteristics. As innovation remains to advancement, we can expect a lot more amazing growths in the future of import engines.

Modern gas injection systems have evolved to supply gas a lot more effectively and precisely into the engine cyndrical tubes, enhancing general engine performance and gas performance - import engines. By integrating electric motors and batteries right into the powertrain, crossbreed engines can supplement the interior combustion engine throughout acceleration or low-speed driving, thereby boosting total efficiency

What are the his explanation essential improvements in engine monitoring systems that are enhancing the performance and performance of modern engines? Engine management systems have undertaken substantial advancements to enhance engine efficiency and performance. From the advancement of turbocharged engines to advancements in fuel injection systems, combination of crossbreed modern technology, boosted engine management systems, and the use of light-weight materials, these technologies have jointly enhanced efficiency, fuel performance, and overall driving characteristics.